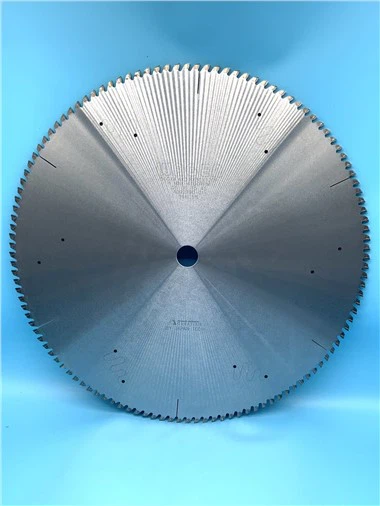

Causes of sharpening cracks in woodworking alloy circular saw blades

Mar 23, 2024

Causes of sharpening cracks in woodworking alloy circular saw blades

Woodworking circular saw blades have high strength and ductility, but they are prone to cracks during sharpening. Why is this? Let's take a look.

Due to the high strength of the carbide saw blade, it is easy to passivate the grinding wheel sand during the sharpening process. If the self-sharpening effect of the grinding wheel is not good, the drilling ability will be lost. , increase the sliding friction, and the sharpening process will generate additional internal stress due to local high temperature, resulting in thermal cracks. The phenomenon of sharpening vibration and cracking is due to factors such as poor rigidity of the boring tool, vibration of the lathe spindle, excessive sharpening residue, unstable clamping, etc. during the sharpening process, resulting in vibration throughout the sharpening process. This will cause the cutter head to break.

Another phenomenon is grinding chipping. During sharpening, the axial and radial vibrations of the grinding wheel are too large, the rotation direction of the grinding wheel is different from the cutting direction of the blade, and the order of grinding the ulnar side and the rear corner is unreasonable. This will cause the blade to break.

After a period of use, the saw blade may need to be sharpened depending on the specific application. What is the criterion for sharpening a woodworking circular saw blade?

Normally, the sound of the saw blade should be uniform and noise-free. However, if the sound is suddenly too loud or abnormal during sawing, you should check immediately to see if the saw blade needs to be sharpened. If you find that there are too many surface textures on the workpiece or the sawing process is often too different, you should also check it at this time. Due to friction during saw blade processing, a certain amount of smoke will be produced, which will be lighter under normal circumstances. If you notice a pungent smell or the smoke is too thick, it is most likely because the saw teeth are not sharp. It must be replaced and repaired.

In addition, there are some situations, such as excessive consumption, burrs on the product workpiece, etc. The saw blade must be checked in time to avoid affecting the processing progress.

What are the advantages of alloy saw blades?

Woodworking alloy saw blade manufacturers introduce here that alloy saw blades are very popular now, of course because of their advantages.

Mainly reflected in: faster sawing speed, improved cutting efficiency, and high work efficiency; low saw blade deflection, no burrs on the cross-section of the seamless steel pipe being sawed, improved workpiece sawing accuracy, and the saw blade To maximize the service life; for a long service life, you can use a saw blade gear grinder to repeatedly grind the teeth. The service life of the sharpened saw blade is the same as that of a new saw blade, which improves productivity and saves money. cost.

Only a very small amount of heat is generated during the sawing process, which can avoid thermal stress at the wound cross-section and changes in material structure. At the same time, the saw blade exerts little pressure on the seamless steel pipe and will not cause deformation of the thick-walled pipe. .