What are the common signs of wear on woodworking alloy saw blades?

Mar 23, 2024

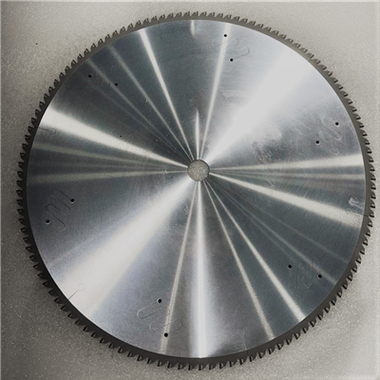

What are the common signs of wear on woodworking alloy saw blades?

Any object will undergo certain wear and tear after use, and alloy saw blades are no exception. However, many people often do not understand the wear manifestations of alloy saw blades, so they are always unable to detect the wear of alloy saw blades early.

From the perspective of resource utilization, damaged alloy saw blades are also misplaced resources that can be utilized.

At present, the reuse of damaged saw blades mainly focuses on extending the service life of saw blades through saw blade grinding, followed by recycling damaged saw blades as waste boards.

Of course, saw blade grinding is not a quick fix for rejuvenation. In many cases of damage to alloy saw blades, cracks in the saw blade base are often difficult to repair through grinding. .

As for the common wear of alloy saw blades, our most common wear manifestations include the following: cracks in the base of the saw blade, scratches on the surface of the base, wear of the saw blade teeth (including tooth loss), and tooth seat wear. wear and tear etc.

Among the many external manifestations of alloy saw blade wear, there is no doubt that cracking of the matrix is often the most fatal. Because the matrix serves as the foundation of the saw blade, once the "foundation" is not strong, the result will be "the earth shakes and the mountains shake". As for the guarantee of the sawing effect, it is even more "a fantasy".

For this reason, when it comes to saw blade grinding, many saw blade manufacturers often conduct a visual inspection of the wear status of the damaged alloy saw blade before officially taking over the damaged saw blade, or obtain the wear status of the saw blade through voice communication. .

After a preliminary understanding of the wear and tear of the saw blade, the saw blade manufacturer will officially take over the saw blade and repair the worn saw blade.

At the same time, there is often a principle for saw blade sharpening, that is, the cost of saw blade sharpening must be lower than the cost of introducing a new saw blade, otherwise it will have the opposite effect.

Of course, the current cost of single-blade saw blade grinding is still controllable, and is significantly lower than the cost of introducing new saw blades. However, the grinding effect during the actual grinding process varies from factory to factory.

Manufacturers that specialize in saw blade grinding will show excellent performance both in terms of the reserve of technical personnel and the technical level of grinding equipment.

Among them, we take saw blade grinding equipment as an example. Currently, the equipment with the best grinding effect often comes from abroad. Among them, the grinding equipment from Germany is the benchmark for saw blade grinding in the industry.

The above is the wear knowledge of alloy saw blades. If you find problems early and solve them early, the use effect will be more guaranteed.