Are there any production process tests for woodworking alloy saw blades?

Mar 23, 2024

Are there any production process tests for woodworking alloy saw blades?

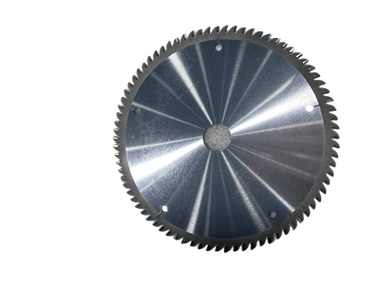

When it comes to the woodworking industry, we all think of woodworking alloy saw blades, which are commonly used equipment in woodworking. So do you know what the inspection process of alloy saw blades is?

1. Detection of hardness change of gear seat after alloy saw blade welding teeth. The saw blade uses three temperatures during the tooth welding process. When the base tooth seat is heated to 650 degrees, the hardness of the base remains unchanged. When heated to 750 degrees, the hardness only increases by 3-5 degrees. At a temperature of 800 degrees, the hardness has reached 55-58 degrees, so the matrix teeth are broken during cutting. The size of the generator with different tooth shapes or saw blade thicknesses is also critical to its impact.

2. Detection of side rake angle and side rear angle of alloy saw blade. Many people choose to use a table when detecting the side rake angle. When detecting the side rake angle, it is affected by the change of the alloy undercut angle or the change of the alloy length value. If the deformation of the base body is added, or it is still not in the center circle, when using a point-surface contact table to measure the side rake angle, it is only an approximate reference value, not an absolute value. The side clearance angle is affected by the size and diameter of the grinding wheel A and B surfaces. And the five different changes of the grinding center line are essentially just a reference value. Rigorous detection still requires the most accurate projection vision device.

3. Detection of deformation of saw blade welding teeth. Material thermal stress or cold tensile force changes will occur during the thermal change of materials. It is mainly caused by many factors such as material, temperature, cooling time, thickness of the workpiece and heating area. According to the measurement state of the base body in the cold state, the unavoidable factors in the next process will bring changes to the welding teeth. At this time, based on the above-mentioned recorded data, we will conduct another inspection along the recorded marks according to the above-mentioned 6 methods, depending on the amount of its deformation. From this analysis, we can also see the harm caused by the welding teeth to the deformation of the base body.

4. Alloy saw blade diameter jump detection. There are three types of states that produce a strong jump. The first is 180-degree eccentric high and low, the second is left high and right bottom or right high and left bottom, and the third is uneven left and right high and low. The first type of hole fit is too poor, and the aperture of the base body is too large, resulting in a 180° eccentricity; the second type only requires that the base body is not in the center when sharpening, causing the left and right grinding heads to not grind on the same center; the third type of grinding wheel has unreliable mechanical accuracy The quality or grinding wheel is not flat and rounded.

5. Alloy saw blade end jump detection. The main factors causing the end jump of alloy saw blades are matrix elasticity and plastic deformation. If the mechanical clip is uneven and bounces, the coordinates of the tooth extraction claw may be unstable. Detection of factors such as grinding wheel quality or uneven concave and convex surfaces and arcs does not allow micrometer measurement due to the wavy or pot-shaped state of the substrate.

The above is the production process of alloy saw blades. I hope everyone can understand it, so that you will know more when using it.