Suggestion And Reason Of Wood Cutting Blade

Feb 27, 2024

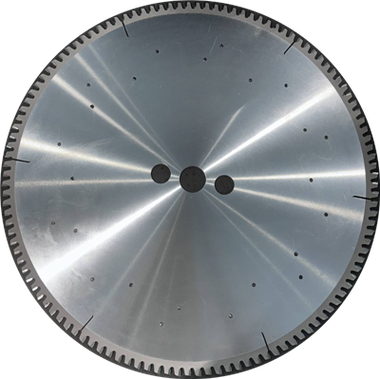

Specializing in the production and operation of carbide circular saw blades, the company has been adhering to the three principles of high starting point, high efficiency and high quality since its establishment, and is committed to developing and producing world-leading products. It is a leading domestic tool technology enterprise. In order to meet the increasingly high technical requirements at home and abroad, a full set of advanced production lines and production technologies were introduced in 1996, and imported raw materials were used to manufacture various types of carbide circular saw blades. With internationally leading technology and sophisticated testing methods, the products fully comply with international standards. The high-quality circular saw blades produced have the characteristics of precise cutting size, smooth surface, high efficiency, long service life and impact resistance. It is widely used in cutting wood, artificial boards, plastics and aluminum alloy profiles. It is an ideal professional tool and is favored by new and old customers at home and abroad.

Multi-blade saws are machine-processed from multiple saw blades, while single-blade saws are operated with a single saw blade. The requirements for a single saw blade are generally not very high, and the real-time quality ratio is slightly worse, and the requirements for many saw blades are also Different, the requirements for saw blades are relatively high. The use of multiple saws generally requires more wood, small saw blades, common saw blades, and high smoothness. 1. Basic data: Single machine spindle speed, single machine processing workpiece thickness and material, single tool outer diameter size and hole diameter (shaft diameter); 2. Selection basis: Calculated by spindle rotation speed and matching saw blade outer diameter, cutting speed: Vaniax OD dx Turn N 60 (m/s) The reasonable cutting speed is generally 60-90 m/s

Specific suggestions: material cutting speed, softwood 60-90 (m/s), hardwood 50-70 (m/s), particleboard, plywood 60-80 (m/s). The cutting speed is too high, the machine tool vibrates, the sound is loud, and the saw The stability of the chip is reduced, the processing quality is reduced, the cutting speed is too small, and the production efficiency is reduced. At the same feed rate, the cutting amount per tooth increases, which affects the processing quality and tool life. Since the relationship between the saw blade diameter d and the spindle speed N is a power function, in practical applications, it is most economical to reasonably increase the speed and reduce the saw blade diameter. 3. Quality/price ratio: As the saying goes: "Cheap goods are not good, and good goods are not cheap." This may be true for other products, but it is not enough for tools; the key is to match. There are many factors at the job site: such as equipment cutting objects, quality requirements, personnel quality, etc. Conduct a comprehensive evaluation and rationally choose and use the appropriate and just right ones to save money, reduce costs, and participate in industry competition. This depends on the mastery of professional knowledge and information on similar products. 5. The cutter head is damaged

Reason: The adhesive on the cutter head is too hard; Solution: Use a soft adhesive saw blade according to the cutting material; 6. The cutter head wears too fast. Reason: The adhesive on the cutter head is too soft (for the material being cut). Insufficient cooling water, loose drive belt or low power or insufficient speed; the saw blade is not perpendicular to the material being cut. Solution: Choose a hard-bonded saw blade according to the cutting material, check the cooling water system, ensure the normal operation of the water pump, ensure the power supply voltage, check the spindle flange, and ensure the perpendicularity between the saw blade and the equipment; 7. Reasons for the loss of the cutter head: During the cutting process, the cutting material slides, causing the cutter head to twist off; the flange wear cannot fix the saw blade, causing the saw blade to twist; the saw blade is subject to a large impact, resulting in the loss of the circular blade;