Sharpening the knife without cutting wood by mistake - a complete collection of woodworking saw blade selection and use techniques!

Apr 27, 2023

In the production process of wooden furniture, all kinds of mechanical equipment are used. Among them, all kinds of knives on the machine are in direct contact with wood and play the role of cutting or milling. If you want to use all kinds of machinery well, you must first understand the tools used in processing.

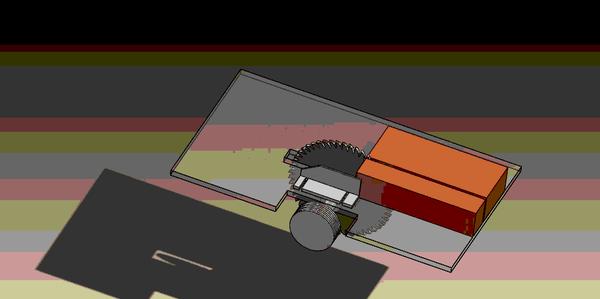

Sawing is an important process in furniture production. Whether it is panel or solid wood furniture, it must first be cut. This is inseparable from a variety of cutting equipment and saw blades. Processing has an important influence, so it is also very important to know the saw blade and understand how to use and maintain it.

Small knowledge of woodworking saw blades

material

According to the different materials to be cut, saw blades have different materials, generally can be divided into high-speed steel saw blades (HSS saw blades), carbide saw blades, alloy saw blades with inserts, diamond saw blades, etc. Woodworking saw blades are generally made of carbide saw blades, which are the most commonly used cutting tools for wood product processing. The quality of carbide saw blades is closely related to the quality of processed products.

Commonly used types of cemented carbide are tungsten-cobalt (code YG) and tungsten-titanium (code YT). Due to the better impact resistance of tungsten-cobalt cemented carbide, it is more widely used in the wood processing industry. The commonly used models in wood processing are YG8-YG15, and the number behind YG indicates the percentage of cobalt content. As the cobalt content increases, the impact toughness and bending strength of the alloy increase, but the hardness and wear resistance decrease. Choose according to the actual situation.

Tooth shape

There are many different tooth shapes for woodworking saw blades. Commonly used tooth shapes include left and right teeth, flat teeth, ladder flat teeth, inverted trapezoidal teeth, dovetail teeth, and rare industrial grade three left and one right, left and right flat teeth wait.

Among them, the left and right teeth are the most widely used, the cutting speed is fast, and the grinding is relatively simple. It is suitable for cutting and sawing all kinds of soft and hard solid wood profiles and density boards, multi-layer boards, particle boards, etc. Left and right saw blades with negative rake angles are usually used for sawing veneers due to their sharp teeth and good cutting quality.

Ladder flat tooth is a combination of trapezoidal tooth and flat tooth. It is more complicated to repair and grind. It can reduce the veneer cracking phenomenon during sawing. It is suitable for sawing various single and double veneer wood-based panels and fireproof panels.

Inverted ladder teeth are often used in the bottom groove saw blade of the panel saw. When sawing double veneer wood-based panels, the groove saw adjusts the thickness to complete the groove on the bottom surface, and then the main saw completes the sawing process of the board to prevent sawing. Mouth chipping occurs.

The flat tooth saw edge is rough, the cutting speed is slow, and the grinding is the easiest. It is mainly used for sawing of ordinary wood with low cost, or for slotting saw blades to keep the bottom of the slot flat.

thickness

The thickness of the saw blade is theoretically as thin as possible, because the saw kerf is a kind of consumption. The material of the alloy saw blade base and the process of manufacturing the saw blade determine the thickness of the saw blade. If the thickness is too thin, the saw blade is easy to shake when it is working, which will affect the cutting effect. When choosing the thickness of the saw blade, the stability of the saw blade and the material to be cut should be considered. The thickness required for some special-purpose materials is also specific, and should be selected according to equipment requirements, such as slotting saw blades, scribing saw blades, etc.

diameter

The diameter of the saw blade is related to the sawing equipment used and the thickness of the sawed workpiece. The diameter of the saw blade is small, and the cutting speed is relatively low; the diameter of the saw blade is large, and the requirements for the saw blade and sawing equipment are high, and the sawing efficiency is also high. The outer diameter of the saw blade is to choose a saw blade with the same diameter according to different circular saw machine models.

The diameters of standard parts are: 110MM (4 inches), 150MM (6 inches), 180MM (7 inches), 200MM (8 inches), 230MM (9 inches), 250MM (10 inches), 300MM (12 inches), 350MM ( 14 inches), 400MM (16 inches), 450MM (18 inches), 500MM (20 inches), etc., the bottom groove saw blade of the precision panel saw is mostly designed as 120MM.

Number of teeth

Generally speaking, the more teeth the saw blade has, the more cutting edges it can cut per unit time, and the better the cutting performance. The chip capacity between the blades becomes smaller, which will easily cause the saw blade to heat up; in addition, if there are too many saw teeth, if the feed rate is not matched properly, the cutting amount of each tooth will be very small, which will increase the friction between the cutting edge and the workpiece, and affect the service life of the blade. Usually the tooth spacing is 15-25mm, and a reasonable number of teeth should be selected according to the material to be sawed.

▲40 teeth saw blade

▲60 teeth saw blade

Applications of woodworking saw blades

basic requirements

The use of saw blades must first meet the following basic requirements. First of all, the appropriate saw blade should be selected according to the design requirements of the equipment. Secondly, the equipped equipment should have safety protection devices, such as: protective cover, power-off brake, overload protection, etc. Once again, professional operators must be installed and used, and wear labor clothing, protective glasses, earmuffs, etc. It is worth noting that when operating manual-feed sawing equipment, the operator cannot wear gloves, long hair should be placed in a work cap, and attention should be paid to ties and cuffs to prevent danger. The use environment should also stay away from fire sources and humid environments.

installation requirements

In order to ensure safety, the installation of woodworking saw blades should be done in the following 5 steps.

1. The equipment must be in good condition, with no deformation of the main shaft, no radial jump, firm installation and no vibration, etc.

2. Check whether the saw blade is damaged, whether the tooth shape is complete, whether the saw board is smooth and clean, and whether there are other abnormal phenomena to ensure safe use.

3. When assembling, make sure that the arrow direction of the saw blade is consistent with the rotation direction of the main shaft of the equipment.

4. When installing the saw blade, keep the shaft center, the chuck and the flange clean. The inner diameter of the flange is consistent with the inner diameter of the saw blade to ensure that the flange and the saw blade are tightly combined. Install the positioning pin and tighten the nut. The size of the flange should be appropriate, and the outer diameter should not be less than 1/3 of the diameter of the saw blade.

5. Before the equipment is started, under the condition of ensuring safety, there is a special person to operate the equipment, jog and idle, check whether the equipment is turning correctly, whether there is vibration, and the saw blade is idling for a few minutes after installation, and it will work normally after no slipping, swinging or jumping .

Requirements

In operation and use, in order to ensure safety and good sawing effect, there are also many problems that need to be paid attention to. When working, the workpiece should be fixed, the wood feed should conform to the direction of the knife, do not apply side pressure or curve cutting, the knife should be fed smoothly, and avoid the blade impacting the workpiece, which will cause damage to the saw blade, or the workpiece will fly out, resulting in accidents ACCIDENT. Once abnormal sound and vibration, rough cutting surface, or peculiar smell are found, the operation must be terminated immediately, check in time, and troubleshoot to avoid accidents.

In addition, when starting and stopping cutting, do not feed the tool too fast to avoid broken teeth and damage. At the same time, the equipment flute and slag suction device must be unblocked to prevent slag from forming into blocks, which affects production and safety.

Saw blade maintenance

If the saw blade is not used immediately, it should be laid flat or hung up by using the inner hole. Do not stack other objects or step on the flat saw blade, and pay attention to moisture-proof and anti-corrosion.

When the saw blade is no longer sharp and the cutting surface is rough, it must be reground in time. Grinding cannot change the original angle and destroy the dynamic balance.

The internal diameter correction of the saw blade, the processing of the positioning hole, etc. must be carried out by the factory. If the processing is not good, it will affect the use effect of the product and may cause danger. In principle, the reaming hole should not exceed the original hole diameter of 20mm, so as not to affect the balance of stress.