Choose The Right Way To See The Blade

Sep 15, 2023

Choose The Right Way To See The Blade

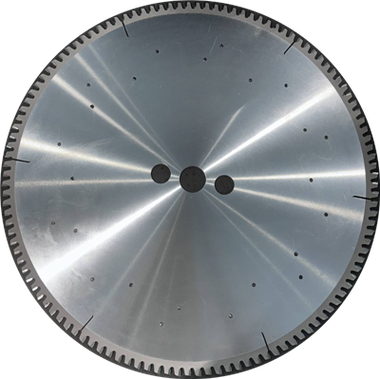

In the processing industry, it is very important to choose the right sawing tool, because only when the saw blade is selected correctly, the processing efficiency and processing quality can be guaranteed. How to choose the right saw blade? Here are some basic ways to choose.

First of all, select the appropriate saw blade tooth profile according to the sawing material. Different blade profiles are suitable for different materials. For example, for metal materials, you can choose a triangular or square tooth profile, while for materials such as wood, you need to choose a curved tooth profile. This allows the blade to break the material more effectively rather than break it when cutting.

Secondly, the diameter of the saw blade and the number of teeth are determined according to the thickness of the sawing material. When we choose the diameter of the saw blade, we can refer to the diameter of the flange, and it is generally recommended that the diameter of the flange is 1/2 to 1/3 of the outer diameter of the saw blade. At the same time, it is also very important to choose the appropriate number of teeth. For some medium hardness materials, it is recommended to keep the feed amount per tooth at about 3 to 4 teeth. It should be noted that the number of teeth should be higher when cross-cutting and less when longitudinal cutting.

Finally, the optimal feeding speed is determined according to the saw blade speed. This is because the feed rate perpendicular to the direction of the blade row affects the contact time between the blade tip and the material, and thus the cut quality. Therefore, it is very important to ensure that the feeding speed is correct. In general, the optimal feeding speed can be calculated based on the speed of the saw blade to ensure cutting quality and maximize processing efficiency.

In short, selecting the appropriate blade tooth shape, blade diameter and number of teeth, as well as the optimal feeding speed, are important factors in improving processing quality and efficiency. Mastering these basic selection methods can more effectively select the right saw blade and improve processing efficiency and quality.