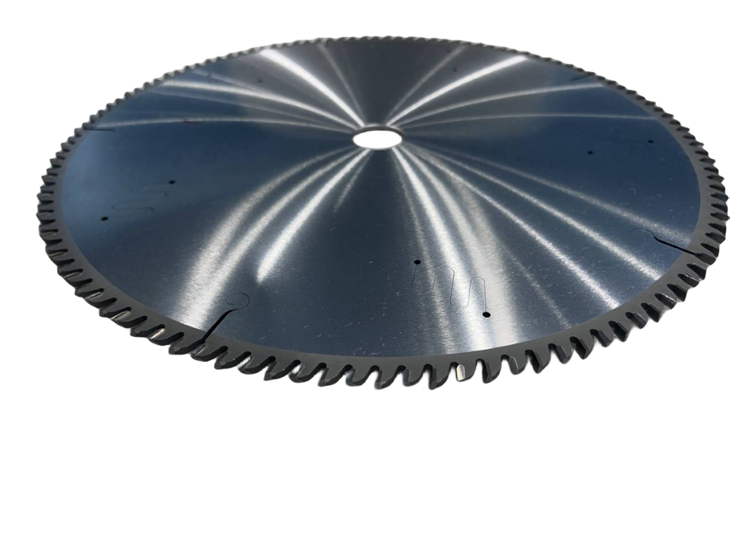

Professional Round Saw Blade Hard Metal Alloy

Stock name: alloy circular saw blade

Specifications: 305×3.4×2.6×25.4×120p

Plating: chrome plating

Sealer: N

Angle: 10/15/15/10

Blade type: C

Sandblasting: Y

Locating hole: N

Keyway: N

Usage: metalworking hard mechanical tools

Buried plug: N

Production cycle: 15 days

Expedited: 7-15 days

Supply Ability :10000 Pieces per month

Customized support:OEM,OEC

Brand Name:WAGEN

Advantage:High speed cut & super long life

Quality Grade:Industria

OEM:Available

Description

Professional Circular Saw Blade Hard Metal Alloy

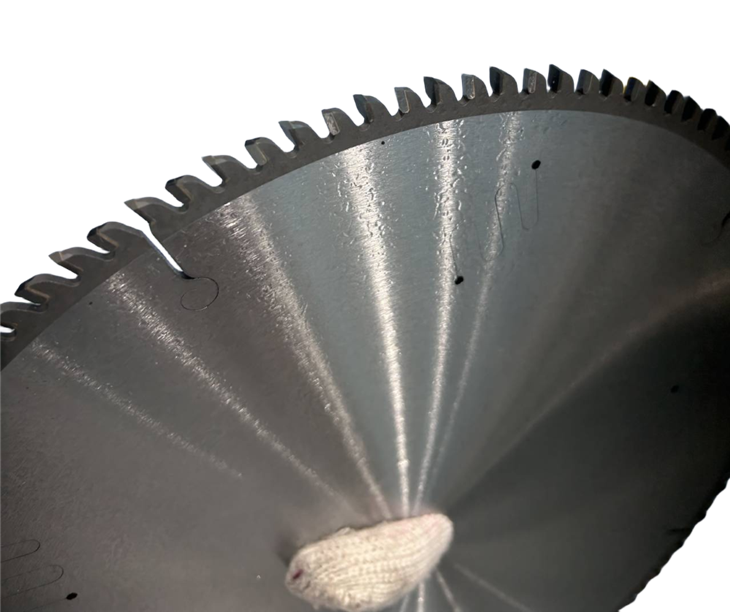

There are different types of specifications of metalworking hard machine tools, the main differences are thickness, diameter and number of teeth, sealing, cutting edge, angle and other aspects.

There are different types of specifications of metalworking hard machine tools, the main differences are thickness, diameter, number of teeth, angle and other aspects.

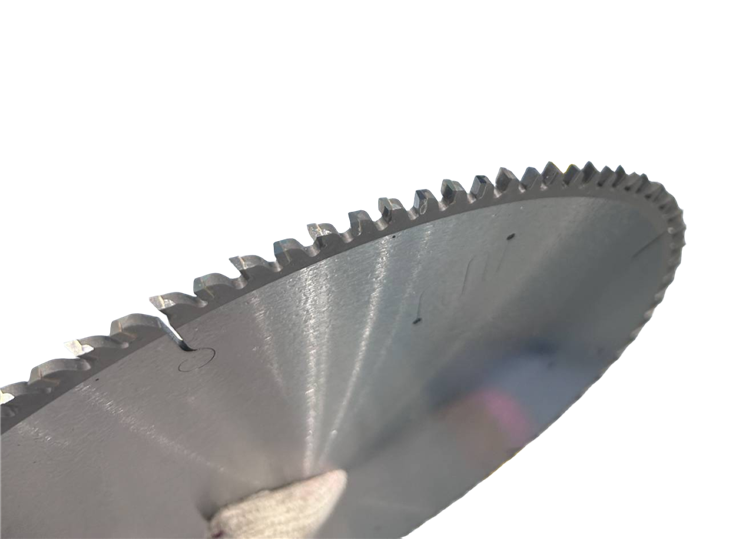

Among them, the choice of the number of teeth has a great impact on the cutting performance and price of the circular saw blade.

In general, the more teeth of the circular saw blade, the more cutting edges can be cut per unit time, and the better the cutting performance. However, if the number of teeth is large, more cemented carbide is needed to manufacture the sawtooth, which makes the price of circular saw blades higher and higher. In addition, due to the excessive density of the saw teeth, the amount of chip between the teeth becomes smaller, which is easy to cause the circular saw blade to heat up and reduce the cutting efficiency of the circular saw blade.

Of course, too few teeth will also affect the cutting performance of the circular saw blade. If the number of teeth is too small, the cutting edge of each tooth will be large, and the cutting force of each cutting edge will be greater. If the feed is not properly matched, it will cause friction between the cutting edge and the workpiece, which will aggravate the wear of the circular saw blade and reduce the service life of the circular saw blade.

Based on the above information, we can conclude that the number of teeth of the circular saw blade needs to be selected according to the actual situation. If you need efficient and high-precision cutting, you can choose a circular saw blade with a higher number of teeth, but the price will also be more expensive. If you need to reduce costs and increase service life, you can choose a circular saw blade with a smaller number of teeth, but this will also require more careful operation.

In short, no matter how many teeth of circular saw blade are selected, it is necessary to follow the correct operation method during use, so as to ensure the cutting performance of the circular saw blade and extend the service life of the circular saw blade.

Product Details:

|

Product Name |

Alloy circular saw blade |

|

Inventory Name |

Professional Circular Saw Blade Hard Metal Alloy |

|

Specification Model |

305×3.4×2.6×25.4×120p |

|

MOQ |

6 pcs, small order is available |

| Electroplating | chrome plating |

|

Sealant |

N |

| Angle | 10/15/15/10 |

| Blade type | C |

| Sandblasting | Y |

|

Sealing |

N |

|

Positioning hole |

N |

| Keyway | N |

| Use | metalworking hard mechanical tools |

| Buried bolt | N |

| Production | 15 days |

| Expedited | 7-15 days |

| Supply Ability | 10,000 Pieces /per month |

| Customized support | OEM,OEC |

| Advantage | High speed cut & super long life |

Packing&delivery:

Packaging details:plastic bag,small pack,carton,pallet,or as your request.

Product Description:

Application: metalworking hard mechanical tools

Hot Tags: professional round saw blade hard metal alloy, China professional round saw blade hard metal alloy manufacturers, suppliers, factory